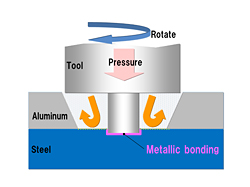

Striving to reduce vehicle weight in order to increase fuel economy, Honda focused on Friction Stir Welding (FSW) and developed a new technology for the continuous welding of steel and aluminum. This technology generates a new and stable metallic bonding between steel and aluminum by moving a rotating tool on the top of the aluminum which is lapped over the steel with high pressure. As a result, the welding strength becomes equal to or beyond conventional Metal Inert Gas (MIG) welding

This new technology contributes to an improvement in fuel economy by reducing body weight by 25% compared to a conventional steel sub frame. In addition, electricity consumption during the welding process is reduced by approximately 50%. It also enabled a change in the structure of the sub frame and the mounting point of suspension, which increased the rigidity of the mounting point by 20% and also contributed to the vehicle’s dynamic performance.

Honda Motor Co., Ltd. today announced that it has newly developed a technology for the continuous welding of the dissimilar metals of steel and aluminum and applied it for the first time in the world to the sub frame of a mass-production vehicle, a key component of a vehicle body frame.